PROJECTS

GLOBAL PROJECTS

CRI was the first company to produce liquid methanol at industrial scale from CO₂ in 2012. Years of industrial-scale operation, together with partnerships on pilot projects and strategic joint ventures, have advanced our proprietary process technology as well as our project and service capabilities.

Our unique experience allows CRI to deliver groundbreaking projects at commercial scale, including the largest and the most efficient CO₂-to-methanol plants in the world.

TIANYING

Carbon Recycling International (CRI) is pleased to announce the signing of a landmark agreement with Tianying Group to leverage its methanol synthesis technology in its large-scale E-methanol production project in Liaoyuan. This marks China’s first large-scale project utilising CRI’s proprietary technology for the production of E-methanol from carbon dioxide. The plant will be the third commercial sized plant commissioned utilising CRI’s technology for methanol production in China.

SAILBOAT

Commissioned in 2023 in China, the Sailboat plant recycles 150,000 tonnes of carbon dioxide annually. It manufactures 100,000 tonnes of sustainable methanol every year, used in the production of olefins and other chemical derivatives. It is the second-largest and most efficient CO₂-to-methanol plant in the world.

SHUNLI

Producing over 110,000 tonnes of sustainable methanol a year, the Shunli plant in China is the largest CO₂-to-methanol plant in the world. Operational since 2022, the plant captures 160,000 tonnes of carbon dioxide emissions a year, contributing to cleaner steel and fuel production.

GEORGE OLAH

Started up in 2012 in Iceland, the George Olah plant was the first industrial-scale production facility ever built that utilizes carbon dioxide waste gas for methanol production. Recycling 5,500 tonnes of carbon dioxide annually, the plant is an at-scale demonstration of the technical, economic and environmental benefits of CRI's Emissions-to-Liquids technology.

CIRCLENERGY

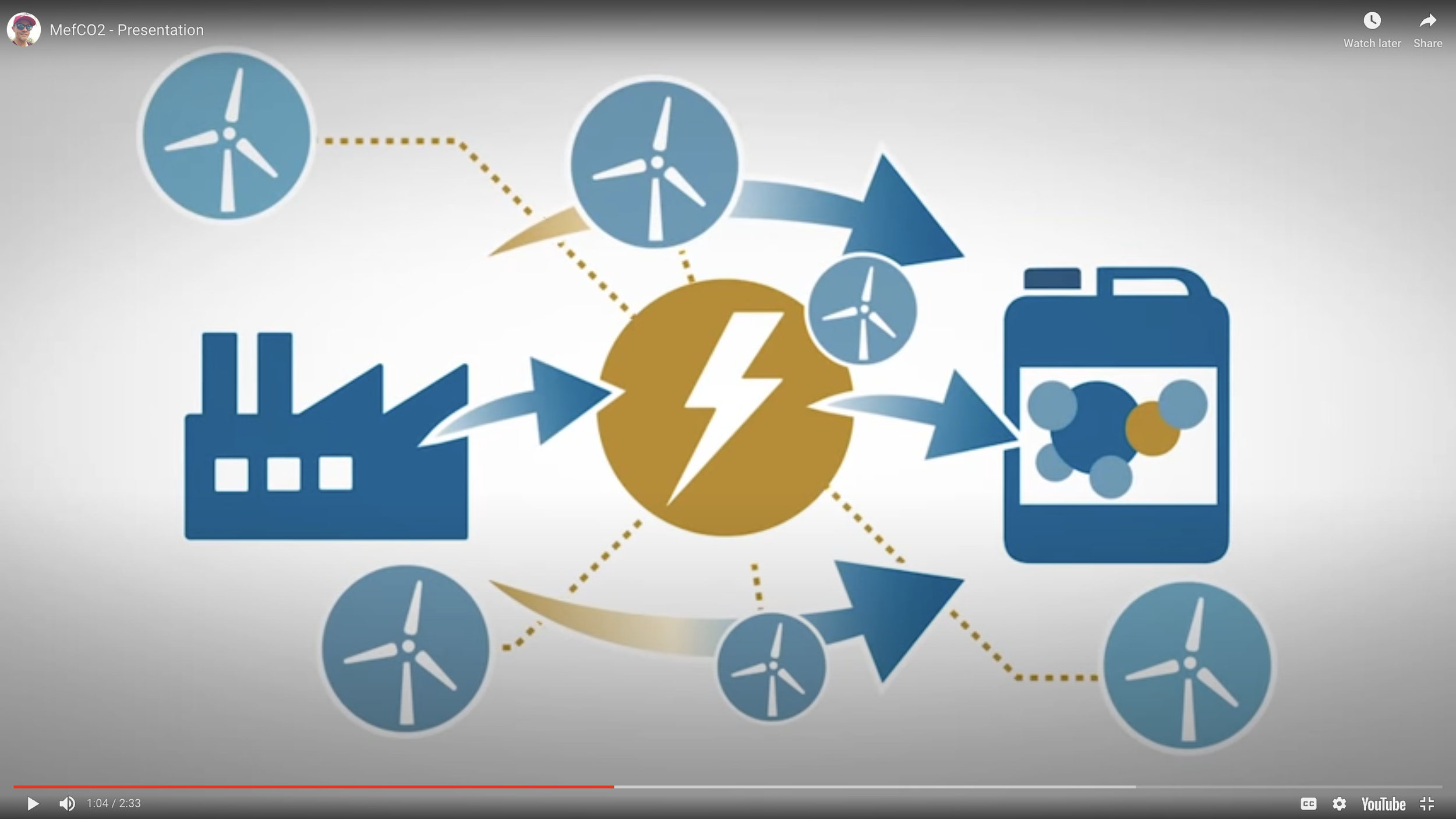

The CirclEnergy project transforms surplus renewable power across Europe into methanol. Acting as a renewable energy storage solution, this methanol addresses the challenges in integrating fluctuating renewable power into the grid and brings to the market a chemical feedstock that can be used in diverse downstream applications.

GAMER

Completed in 2022, funded by a 3 million EUR EU Horizon 2020 grant, the GAMER project developed a high-temperature electrolyzer to enhance renewable hydrogen production. The technology demonstrates superior efficiency, offering industrial producers a more competitive and sustainable way to manufacture green hydrogen.