TECHNOLOGY

CARBON DIOXIDE EMISSIONS TO RENEWABLE METHANOL VALUE

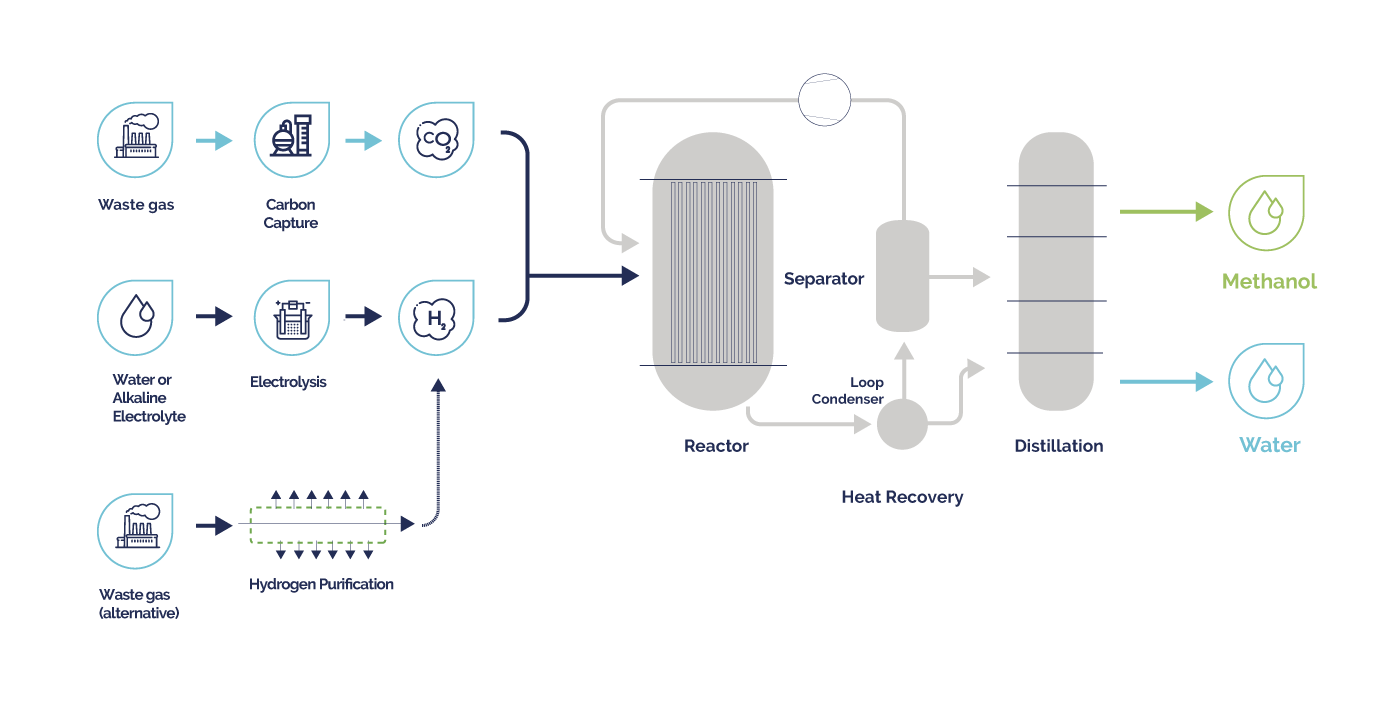

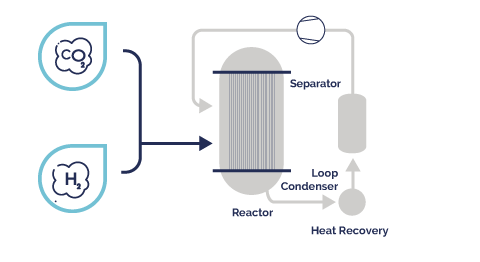

CRI’s patented Emissions-to-Liquids™ (ETL) technology transforms carbon dioxide and hydrogen into

methanol, for a greener, more renewable source of energy and chemical feedstock.

ETL is the most efficient CO₂ to methanol synthesis technology available on the market.

We are the first and only company to have realised CO₂ to methanol plants at commercial scale.

-

TECHNICALLY MATURE

-

INDUSTRIAL SCALE

-

ECONOMICALLY COMPETITIVE

Beginning in 2006, CRI has gained a real head start in operations, engineering and project execution.

Our process is technically mature having spent over a decade solving the challenges of emissions capture and conversion.

In 2012 we were the first company to produce renewable methanol at an industrial scale and 2022 saw the commissioning of the world’s first 110,000 tonnes/year capacity recycled carbon methanol production plant.

CRI’s EMISSIONS-TO-LIQUIDS,

RENEWABLE METHANOL PROCESS

”ETL”

-

RENEWABLE METHANOL

(E-METHANOL)

Hydrogen produced from water electrolysis using electricity from renewable sources, combined with CO₂.

-

RECYCLED CARBON METHANOL

(LOW CARBON METHANOL)

Hydrogen from by-product or waste gas,

processed and combined with CO₂.

Our technology can help partners to produce renewable or recycled carbon methanol competitively

at market prices without any dependence on subsidies. It can be deployed at all manufacturing sites

which emit CO₂ to atmosphere with access to renewable energy through the grid.

KEY BENEFITS OF CRI’S CARBON DIOXIDE TO METHANOL PROCESS

Using CO₂ to produce green methanol can provide huge environmental benefits and there are significant technical

advantages inherent in our process, as a result of CRI’s expertise and innovations.

-

EFFICIENT CONVERSION

Precise adjustment of CO₂:H₂ without reforming equipment

Surplus streams eliminated

Low by-product formation

Reduced energy consumption

No additional CO₂ emissions

-

LOAD FOLLOWING CAPABILITY

Provides important energy storage capability to the grid

Dynamically adjusts to availability of electricity or hydrogen

High turndown and operational flexibility

Enables project viability using highly variable renewable electricity sources

-

SYSTEM SCALABILITY

No dependence on scarce natural resources

Faster times to market

Higher replicability – lower scaling costs

Single standardised reactor design

Accommodates different feedstock availability

Simple logistics, easy to install – modular skid-based equipment

Workshop fabricated ensuring process equipment quality

-

HETEROGENOUS RAW MATERIAL SOURCES

Tailorable to suit different feedstock availability and calibres: e.g. manufacturing or power generation

Deployable at all sites emitting CO₂ and/or H₂ offgas

Adaptable to different sources of CO₂ and H₂

-

SMALL ENVIRONMENTAL FOOTPRINT

Zero impact on food chain or land use

Continuous operation with reduced risk of unstable reaction conditions

Less toxic gas mixture compared to conventional syngas

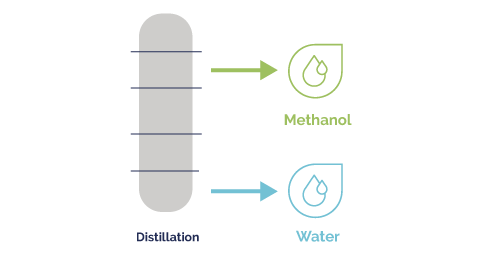

Main by-products are oxygen and water.

MILESTONE ETL TECHNOLOGY DEVELOPMENT PROJECTS

CRI technology has been at the heart of the renewable methanol industry’s most transformative projects.

Each one demonstrates the technical maturity of our ETL technology and our expertise in its application.

-

GEORGE OLAH RENEWABLE METHANOL PLANT

World’s first production of fuel from CO₂ at an industrial scale in Iceland

World’s first industrial scale production of fuel from CO₂

World’s first e-fuel production to receive a recognised certification for carbon intensity

World’s first power-to-liquids facility to implement large-scale electrolysis.

Second generation reactor technology demonstrated

-

MEFCO₂ Project

CO2-to-Methanol pilot project in Germany

ETL adaptability to heterogenous CO₂ sources

ETL load-following capability for efficiency enhancement in renewable power generation.

-

THE SHUNLI CO₂-TO-METHANOL PLANT

Commercial scale production in China

First commercial scale Emissions-to-Liquids (ETL) plant

World’s largest production of fuel from CO₂

110.000 tons low-carbon intensity methanol from 150.000 tons CO₂, commissioned in 2022

CO₂ sourced from limestone and coke production facility.